Navigation

Share this Subscribe to our mailing listArticles Hierarchy

ebbits

|

ebbits Enabling the Business-Based Internet of Things and Services |

EU project (IP) Start 2010 Finish 2014 www.ebbits-project.eu |

|

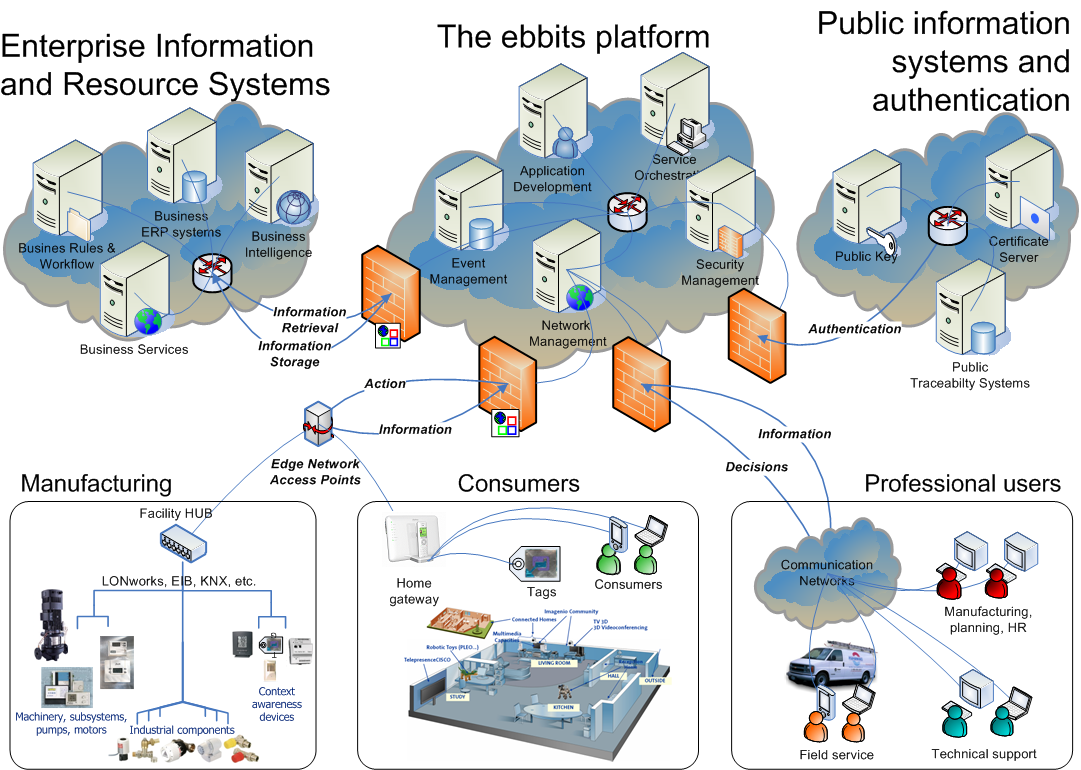

The ebbits project is a 4-year project doing research in architecture, technologies and processes, which allow businesses to semantically integrate the Internet of Things into mainstream enterprise systems and support interoperable real-world, on-line end-to-end business applications. It provides semantic resolution to the Internet of Things and hence presents a new bridge between backend enterprise applications, people, services and the physical world, using information generated by tags, sensors, and other devices and performing actions on the real-world. Rationale The Internet of Things is revolutionising the enterprise and businesses environments. The introduction of RFID technologies has already enabled automated processes in logistics and elsewhere in the business system, but there is an emerging need to enabling new classes of applications combining virtual and physical world information from users, data repositories, devices and sensors into intelligent services based on an open architecture. Trillions of devices are - or will shortly be - able to communicate with each other, with users or other people, and with enterprise and public information systems and thus open the way towards the Internet of Things and Services. The multitude of tags, sensors, and actuators provide physical world information to be used to optimise business processes and create new business opportunities. However, given the enormous amount of heterogeneous devices, sensors and actuators embedded in systems already existing in the market, the diversity of the producers and manufactures, the different clock speed of technology (from several decades to some months), and the potentially global distribution of final products (once they leave the controlled manufacturing and distribution environment), there is a pressing and clear need for technologies and tools that can add, implement and exploit the intelligence and interoperability embedded in individual devices, manufacturing environments and global ubiquitous networks. The enterprise world at large needs a platform to enable, deploy and maintain the Internet of Things and Services and integrate the physical world in their business management platforms and enterprise systems. It also needs a smart platform for reduced time to market, faster deployment of service changes, customisation and scalability, while at the same time building on their enormous installed base of industrial assets. It needs to have context-aware services processing physical-world events and performing action on the physical world. And it needs it for production and energy optimisation, authentication and traceability, and a wealth of other high-value intelligent services aimed to improve their business performance in the future. Architecture The ebbits platform will feature a Service oriented Architecture (SoA) based on open protocols and middleware, effectively transforming every subsystem or device into a web service with semantic resolution. The ebbits platform thus enables the convergence of the Internet of People (IoP), the Internet of Things (IoT) and the Internet of Services (IoS) into the “Internet of People, Things and Services (IoPTS)” for business purposes. The SoA approach allows for distribution of intelligence between the edge network and the centralised business/process information system. Applications will be launched as bundles of service components, each of which can be assigned to a network node (i.e. manufacturing cell level, shop floor level, operator level, point-of-sale, home environment), which is optimal for the overall execution of the application. A Service Orchestration Manager federates the execution of the distributed services with the aim of achieving the overall objectives of the application. The ebbits platform thus offers an open governance system as an alternative to centralised or centrally owned and administered infrastructure components. The ebbits platform may thus eliminate centralised gatekeeper lock-in of critical business or process functionalities. Physically, the ebbits platform consists of subsets of production servers for data management, event management, security, application execution and communication. All servers interoperate in an open architecture on the basis of web services and are thus completely platform agnostic and scalable. A software development toolkit allows for rapid development of new ebbits applications. The platform is visualised in Figure 1.  Figure 1. Architectural overview of the ebbits architecture The ebbits platform bridges the gap between virtual enterprises and public information systems, human users and “things” in the physical world. The ebbits platform creates a ubiquitous communication infrastructure that automatically and dynamically connects to sensors and devices in the physical world in e.g. manufacturing facilities or in private smart homes. It further connects to mainstream backend information systems, public authentication systems and regulatory information sources using semantic web services. It finally connects to human users in dispersed geographical locations such as professional users in technical support, field service and other business environments as well as ordinary consumers in shops or at home. The main technical features and components in the ebbits platform are:

Expected Project Outcomes  An ebbits IoPTS application with real-time optimisation metrics, including energy savings, in manufacturing processes will be developed, implemented and demonstrated. The optimisation metrics will be incorporated in the Overall Equipment Efficiency (OEE). The OEE index is used in most manufacturing companies as a key metric in TPM (Total Productive Maintenance) and LEAN Manufacturing to provide a consistent way of measuring the effectiveness of the production. An ebbits IoPTS application with real-time optimisation metrics, including energy savings, in manufacturing processes will be developed, implemented and demonstrated. The optimisation metrics will be incorporated in the Overall Equipment Efficiency (OEE). The OEE index is used in most manufacturing companies as a key metric in TPM (Total Productive Maintenance) and LEAN Manufacturing to provide a consistent way of measuring the effectiveness of the production. The OEE index is the product of three factors: Availability, Performance, and Quality. By adding the energy consumption parameter we are able to define a new optimisation tool, the OEEE Overall Equipment and Energy Efficiency index. Adding the energy component to this index will allow European industry to not only focus on production optimisation in economic and resource terms, but also in energy terms. Using the ebbits platform and existing smart home environments integrated in the IoPTS, an ebbits prototype business application will demonstrate how consumers can achieve not only comprehensive and reliable information of the life-cycle history of the food, their families are going to eat, but also useful information such as recipes that greatly enhance their experience.  Food packages bought by the consumers are tagged with RFID or barcode identification. The appropriate readers are installed in handheld PDAs, refrigerators or other places, where foodstuff is normally prepared. The smart home environment automatically discovers and configures the readers and locates a suitable display device in the home, such as a PDA or a TV. Food packages bought by the consumers are tagged with RFID or barcode identification. The appropriate readers are installed in handheld PDAs, refrigerators or other places, where foodstuff is normally prepared. The smart home environment automatically discovers and configures the readers and locates a suitable display device in the home, such as a PDA or a TV. When a package of food passes by the reader, the food is identified and publicly available electronic communications services are consulted for updated information about the actual product. The information to be obtained encompasses all the steps that the meat has passed from the farm, via the slaughter house, the meat packager, the wholesaler, the retailer and until it reaches the consumer’s home. The consumer can not only see when the meat left the farm and when it arrived in the slaughterhouse, but he/she can also see the electronic certificates of all the authorized actors in the value chain. The scientific outcomes of the project are:

|

||

In-JeT’s role in the project In-JeT is the chief vision-owner of the ebbits project. As manager of the workpackage on requirements engineering, we are managing the iterative requirement process and develop procedures for capturing Lessons Learned and perform requirements re-engineering, constantly keeping the project aligned with its objectives and vision. In-JeT is also engaged of the workpackage on business modelling, where we, together with partners, develop concepts and methods for value models and process models and create enterprise framework models for life-cycle management in the domains of manufacturing and agriculture. On the dissemination and exploitation side, we develop and maintain the projects’ dissemination strategy and the ebbits website. Finally In-JeT also chairs the Technical Advisory Board. |

||

Partners Fraunhofer Institute for applied Information Technology, Germany (Coordinator) CNet Sweden AB, Sweden (Technical coordinator) SAP Research, Germany Comau S.p.A., Italy Technical University of Kosice, Slovakia Istituto Superiore Mario Boella, Italy TNM A/S, Denmark In-JeT ApS, Denmark Intersoft AS, Slovakia |

||

| Funding Funded by the European Commission - 7th Framework Programme for Research: http://cordis.europa.eu/fp7/ict/ Project budget: 11.9 m€ Project funding: 8.3 m€ Project start date: 1 September 2010 Project end date: 31 August 2014 |

|

|

|

|

||